Customized belting solutions tailored to your needs

We are dedicated to supporting you throughout your entire process, from concept and planning, to design, installation, and maintenance of new and retrofit belting systems. That collaborative approach drives us to provide world-class technical support and service as we

co-engineer the best results together with you.

co-engineer the best results together with you.

Habasit offers a unique range of online tools, including the well-known SeleCalc engineering programs used by engineers worldwide to select and calculate the optimal belting solution for specific application needs.

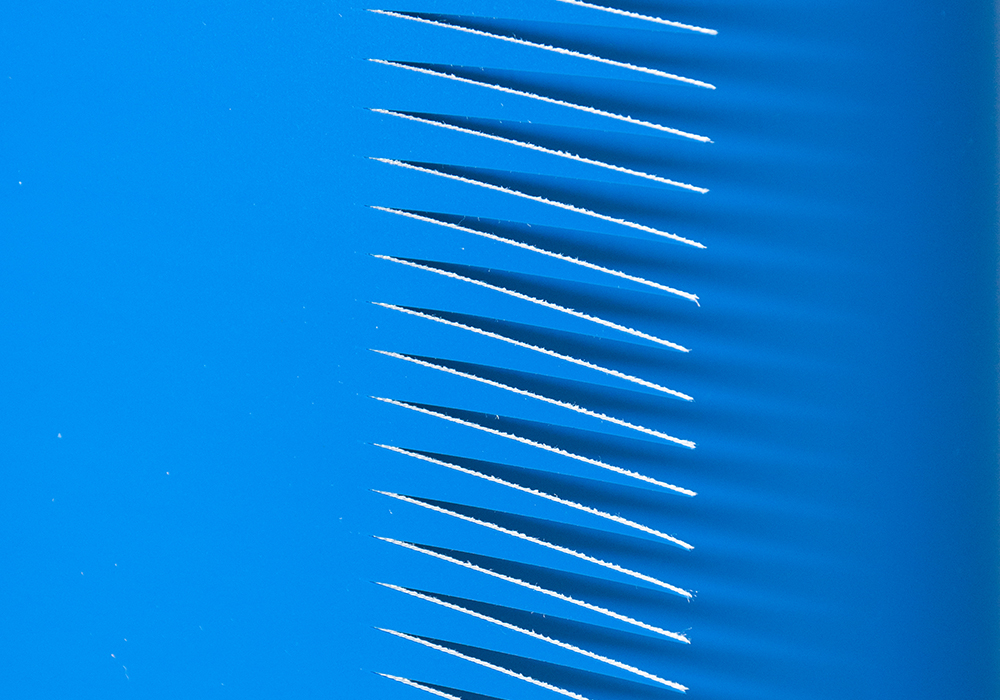

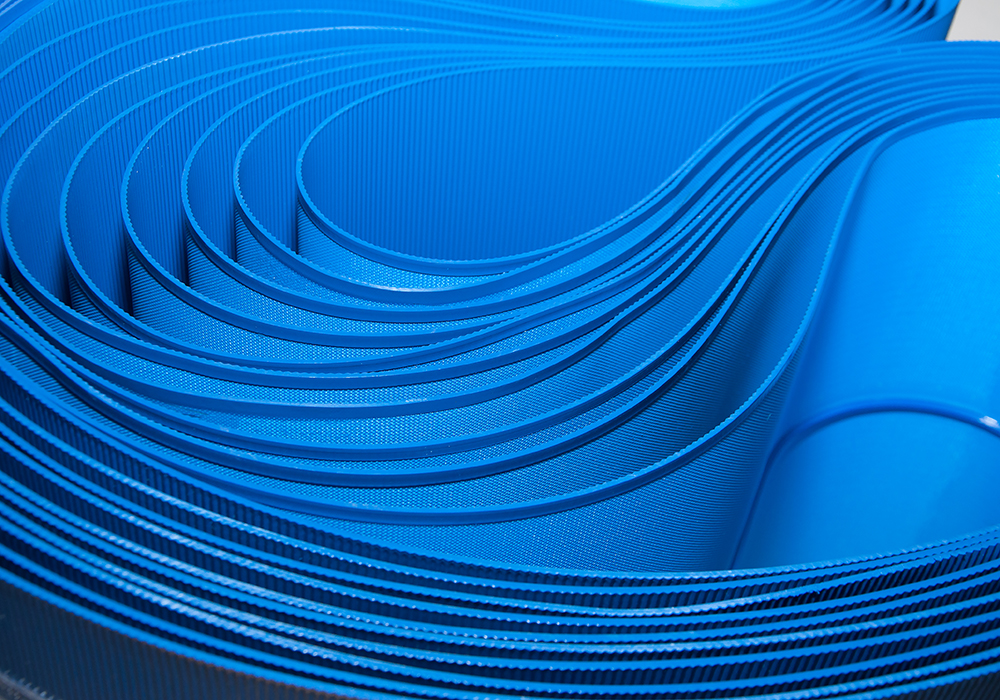

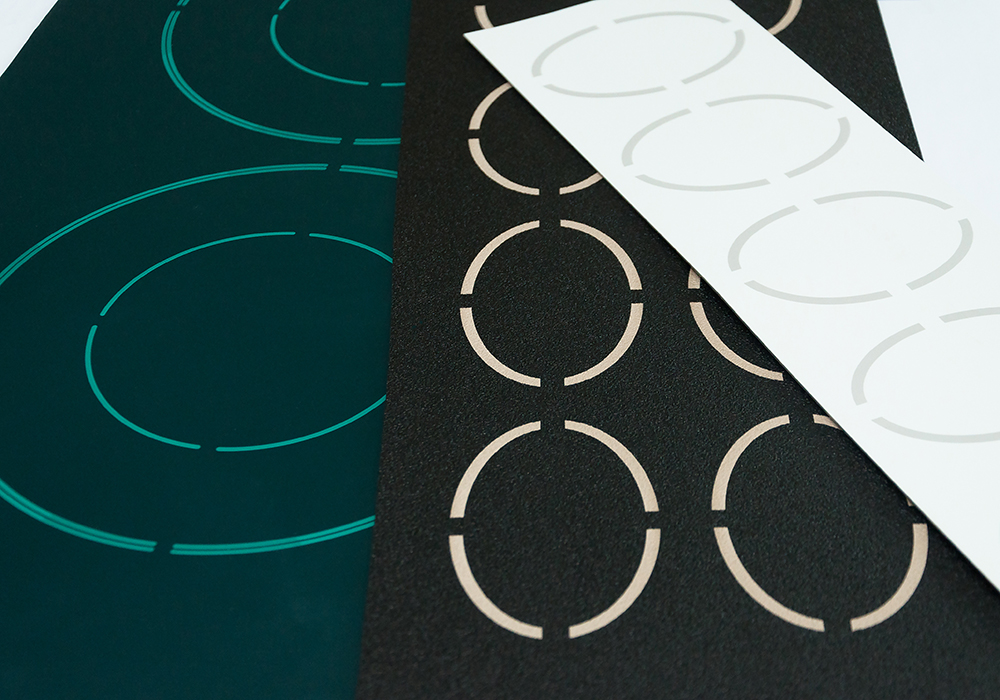

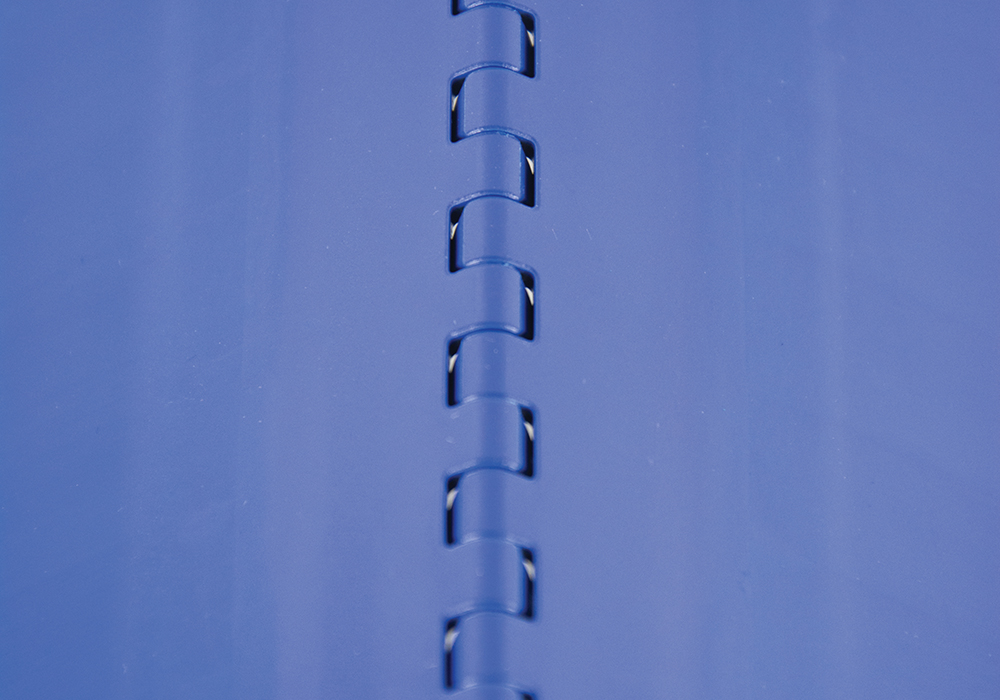

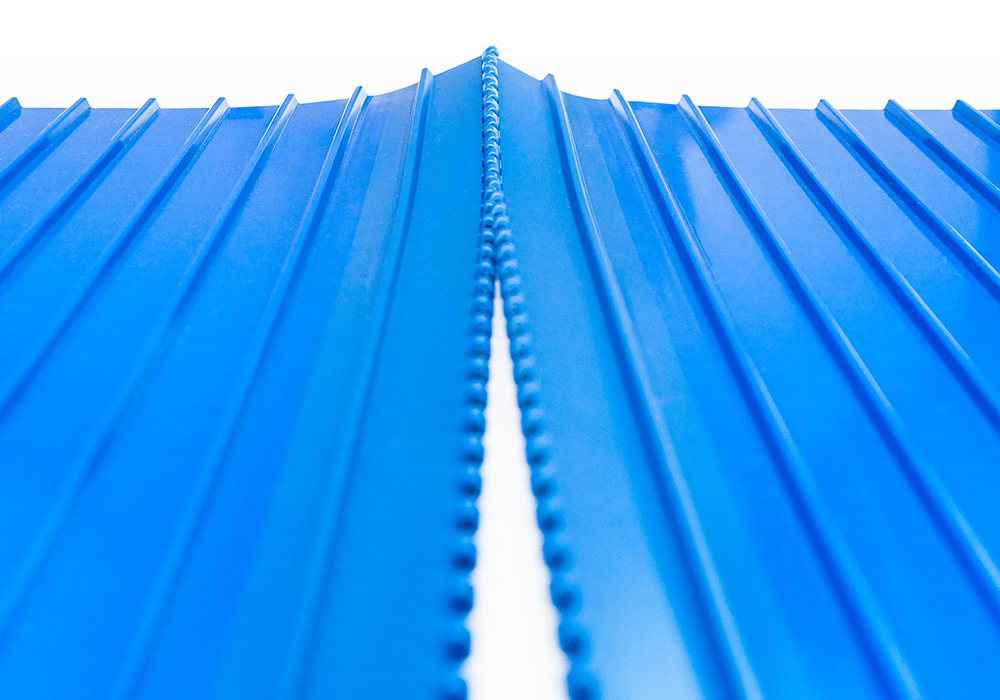

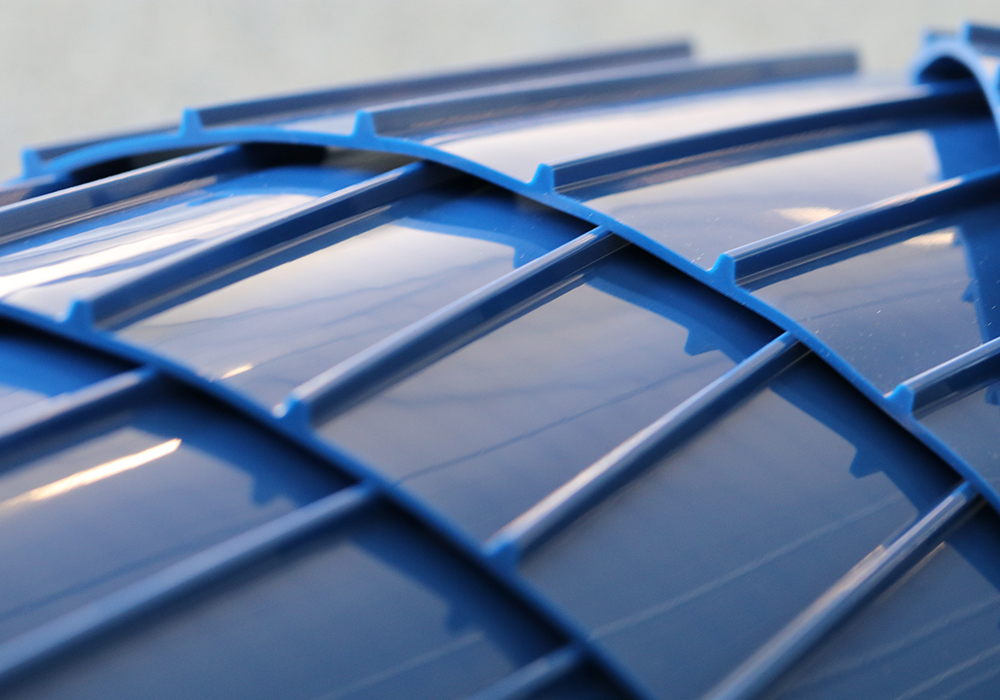

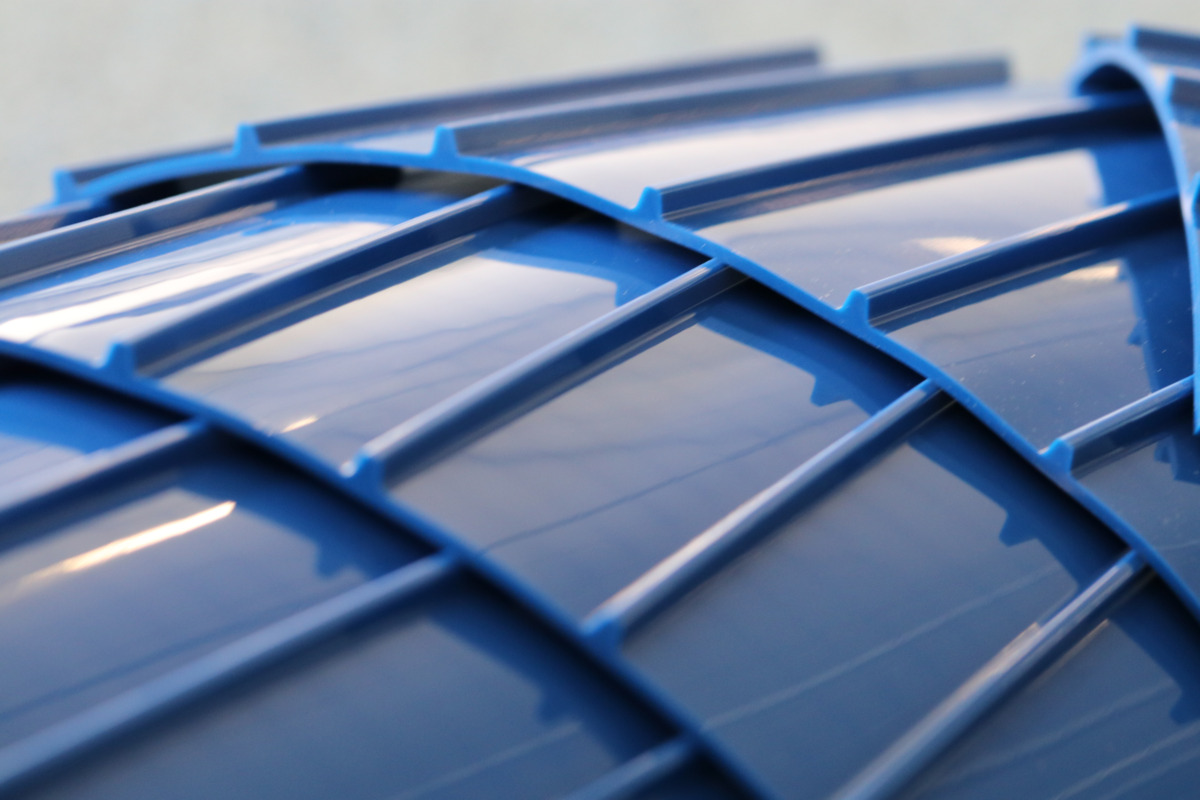

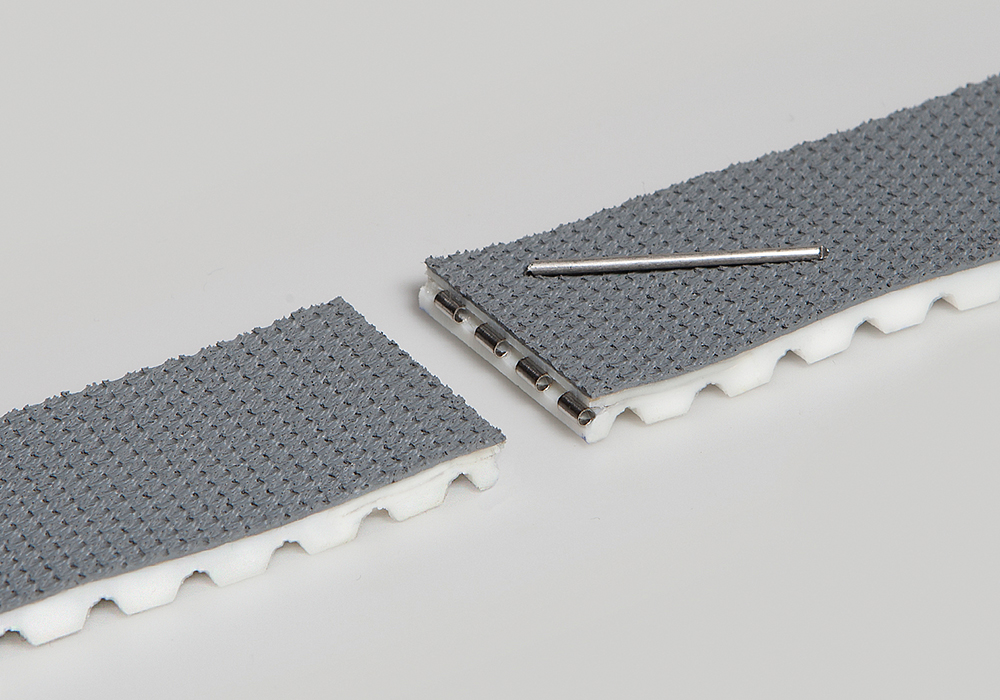

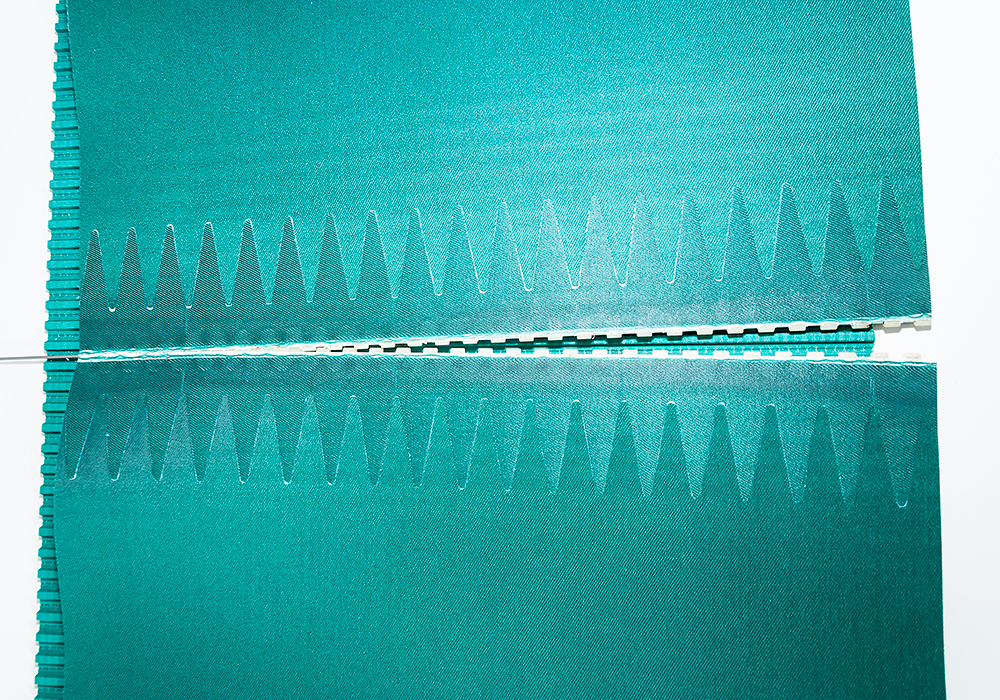

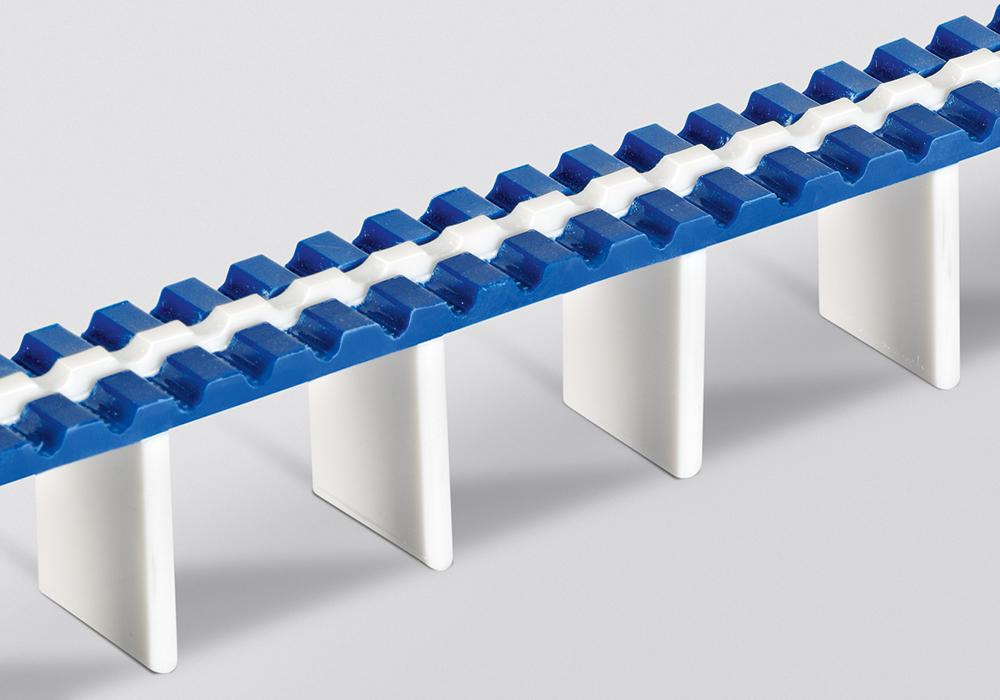

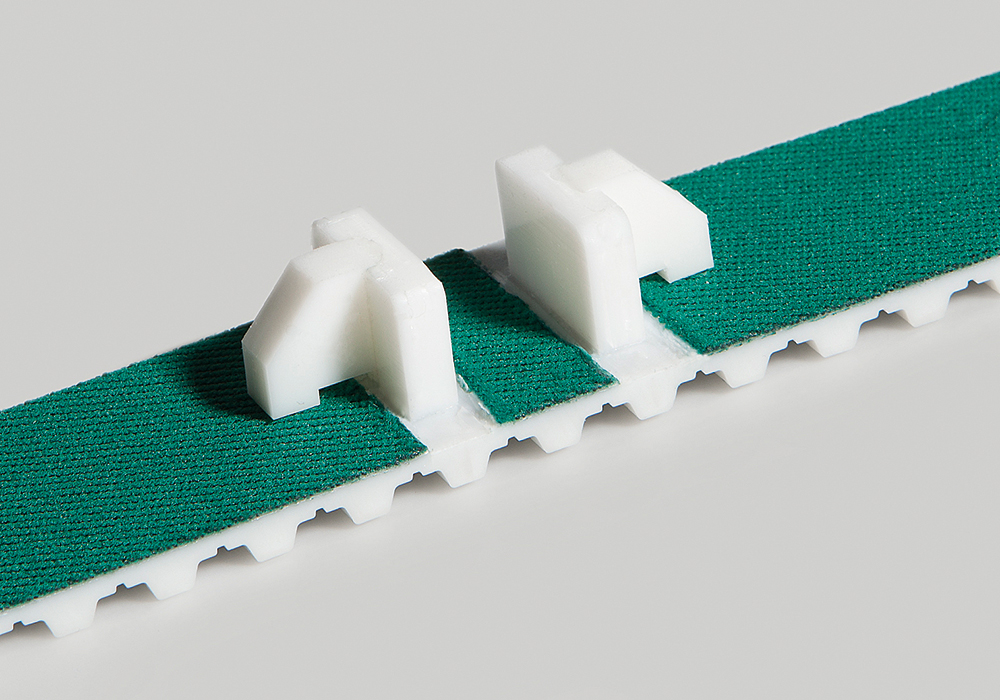

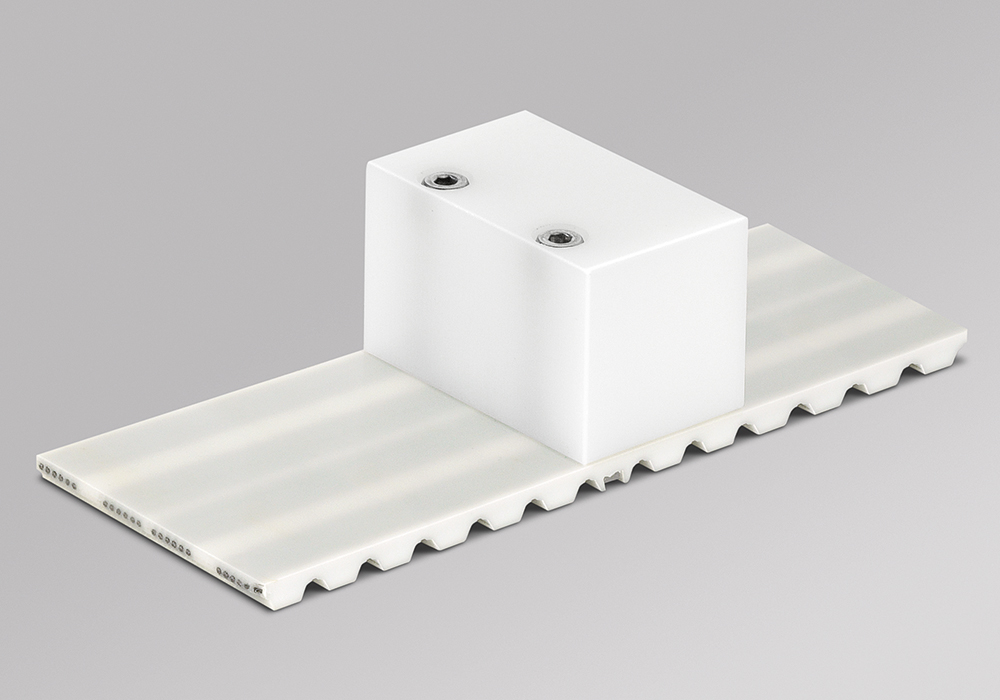

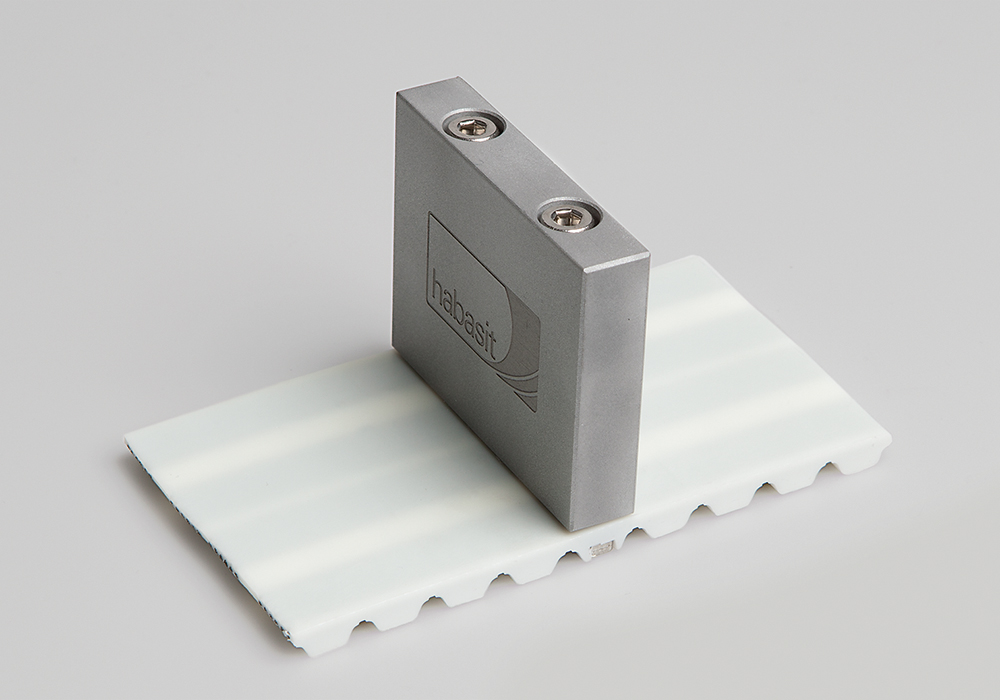

Fabric Belts

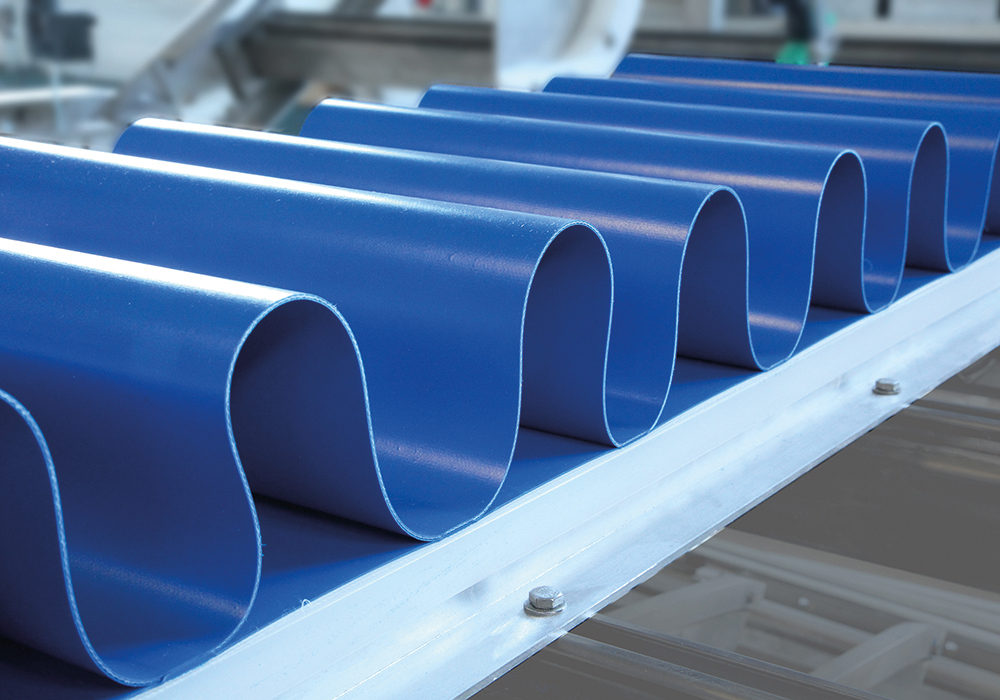

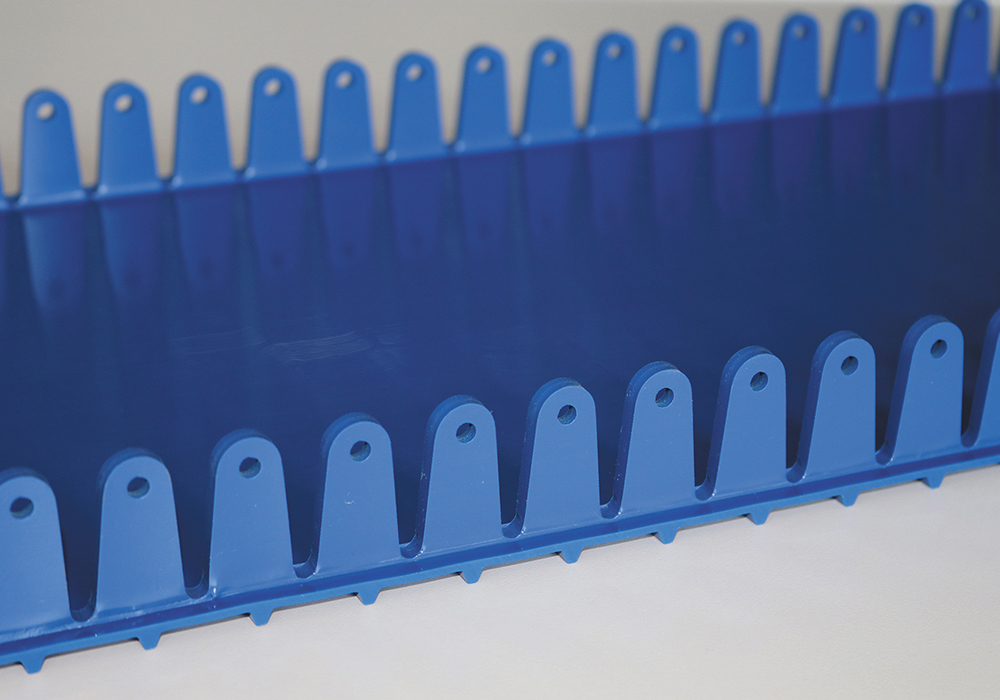

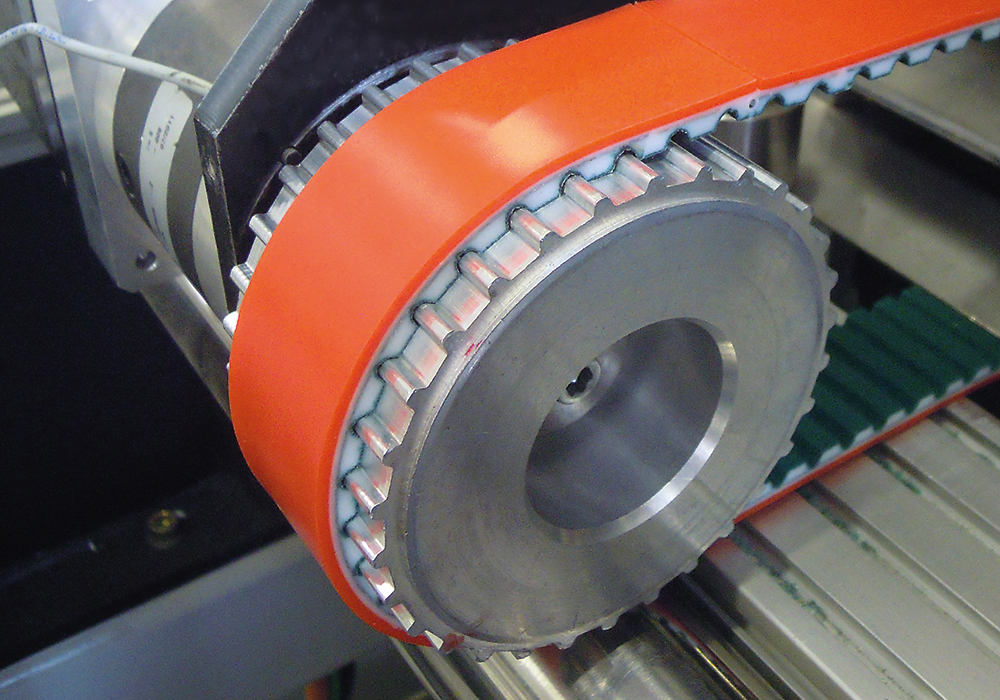

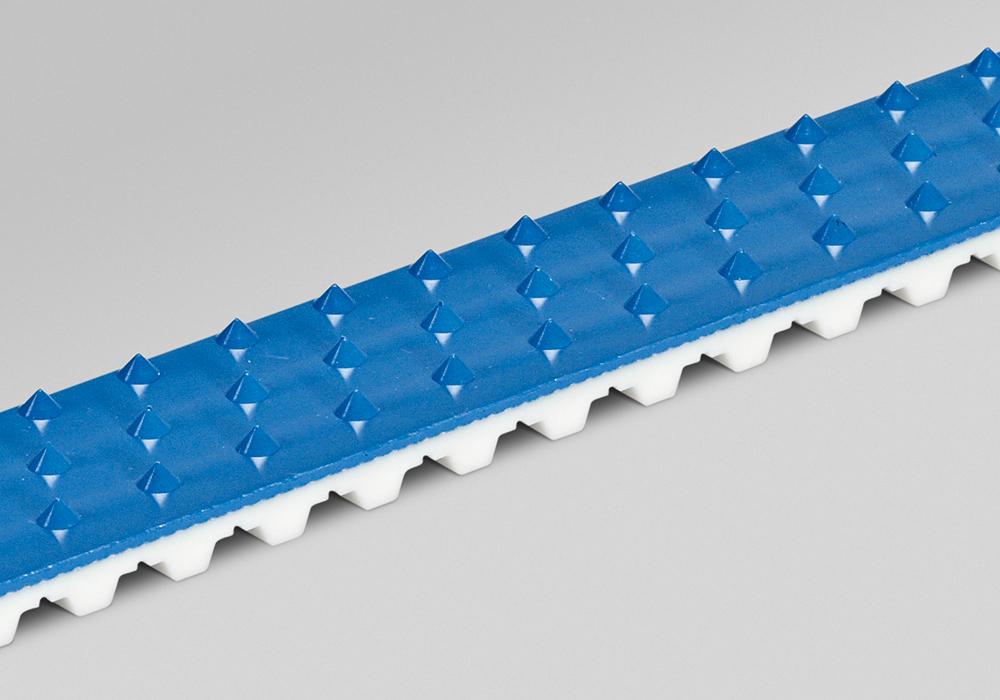

Monolithic Belts

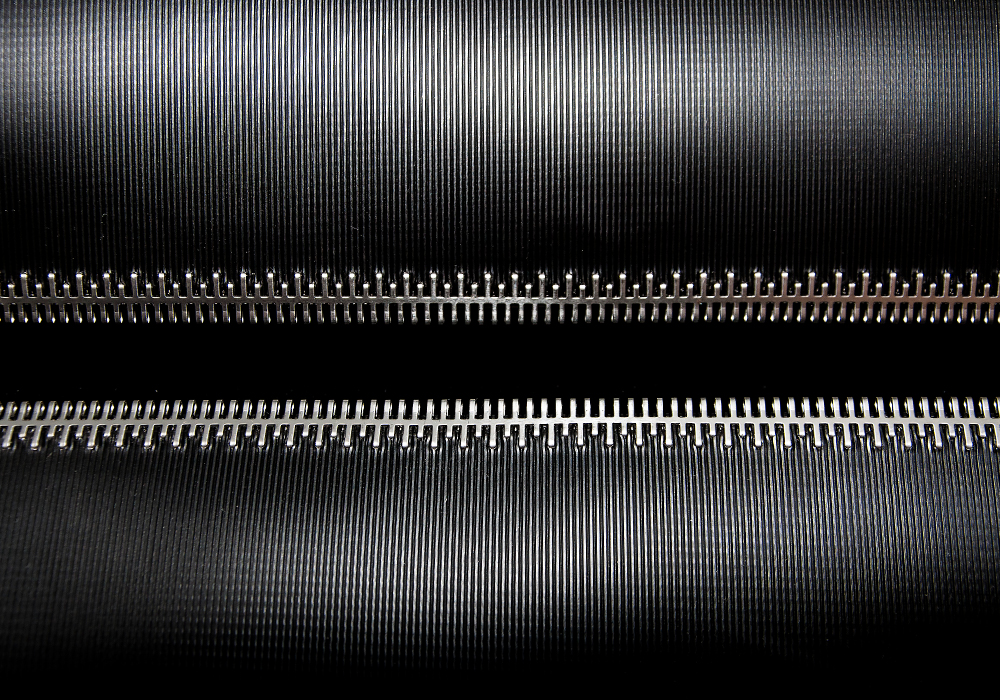

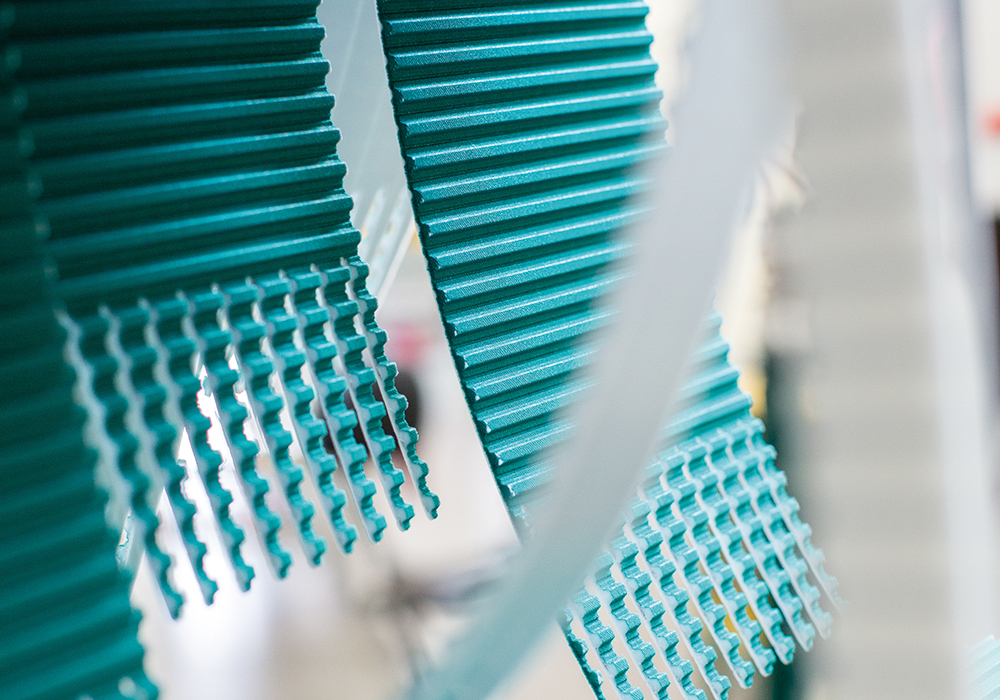

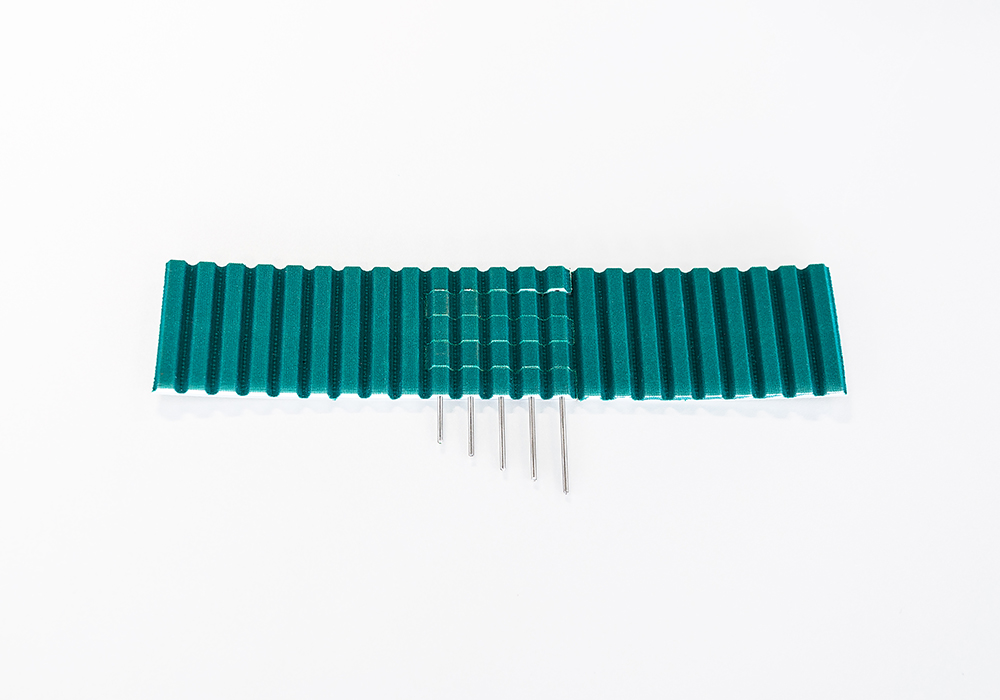

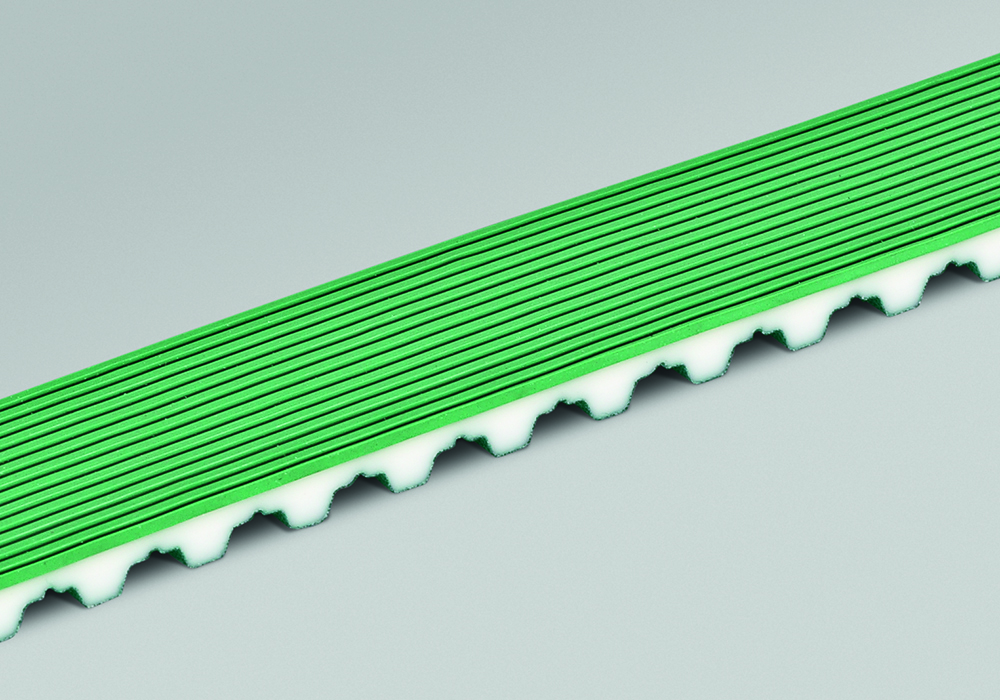

Timing Belts

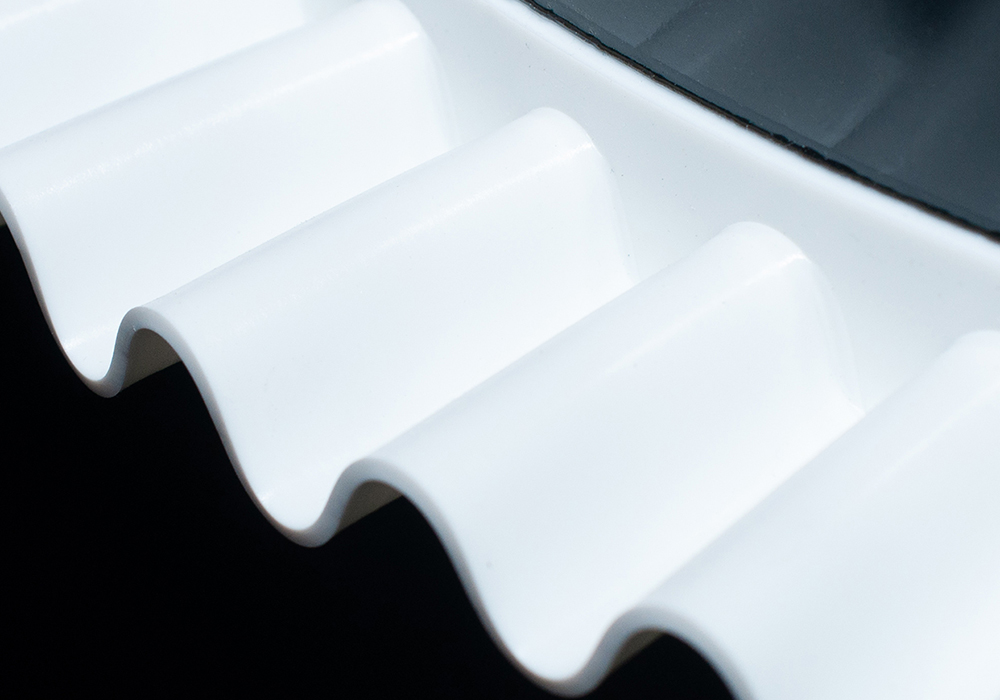

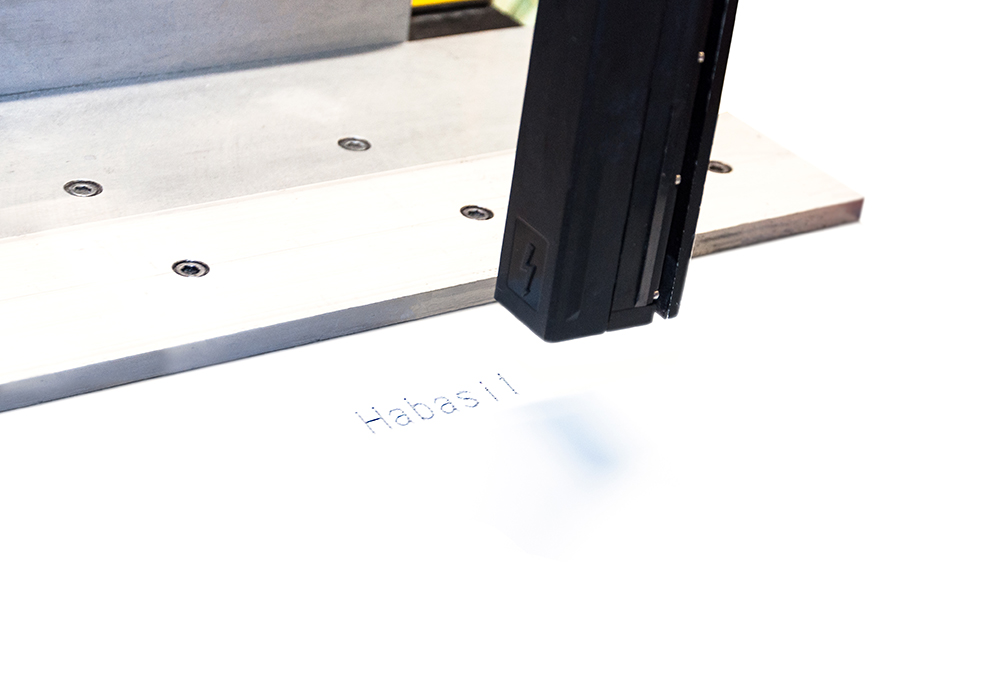

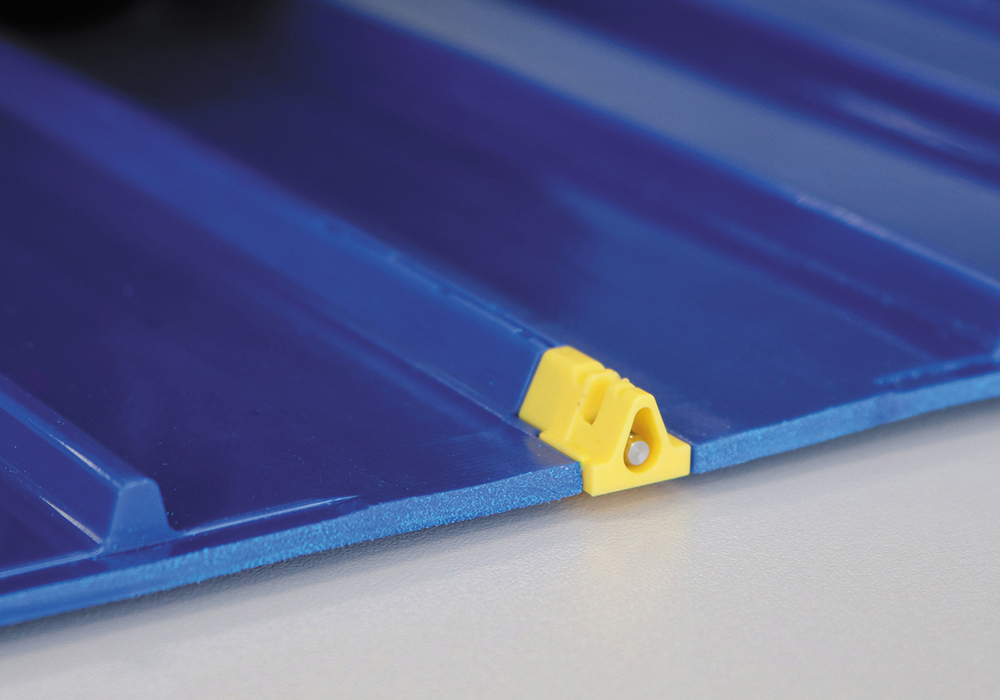

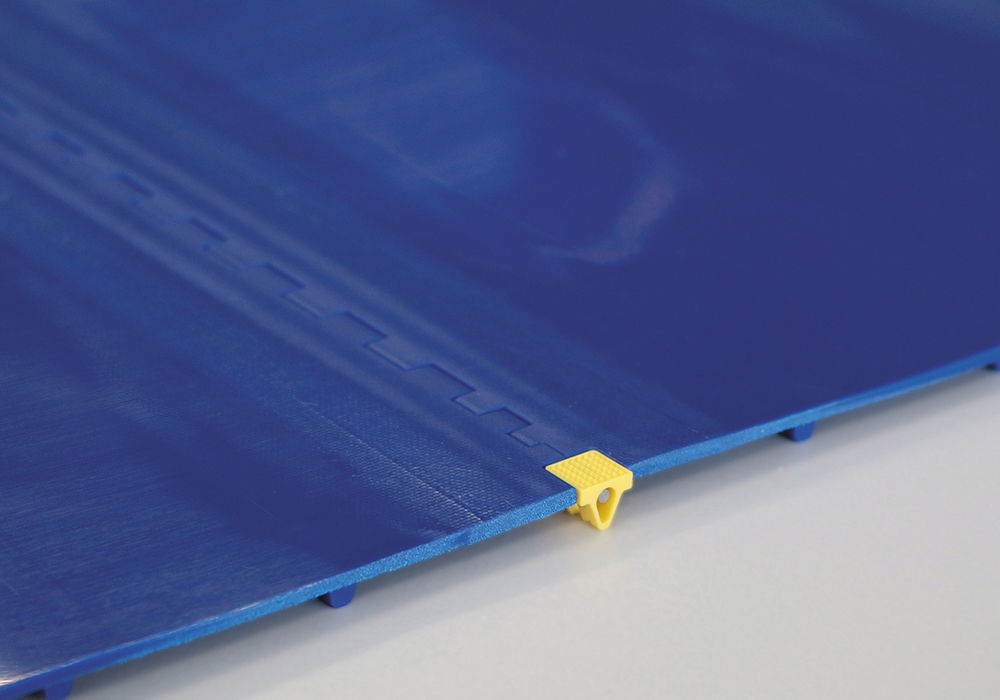

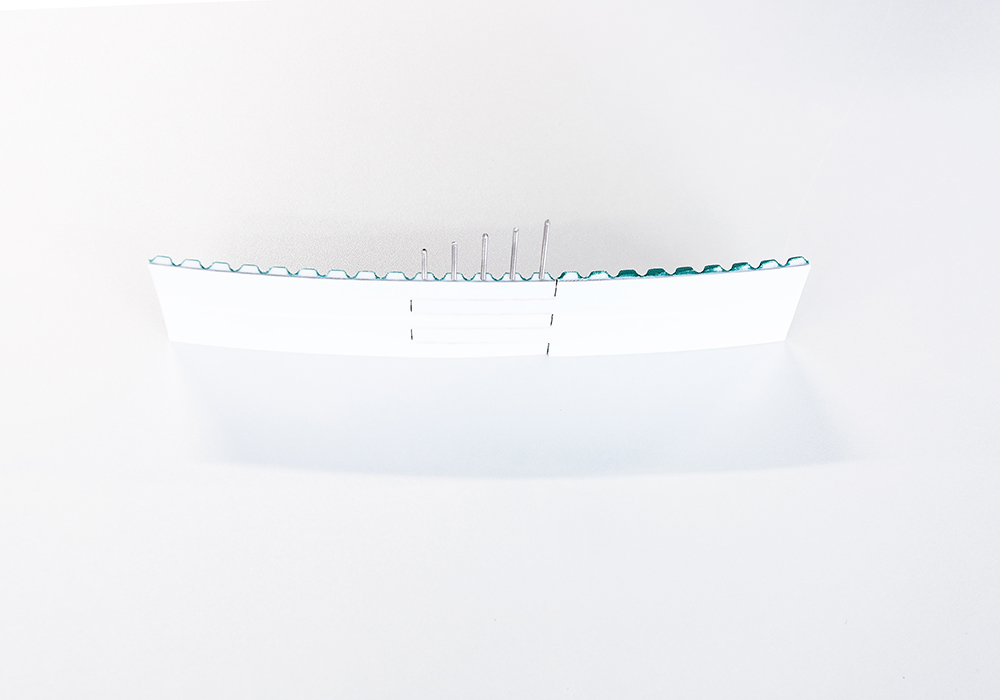

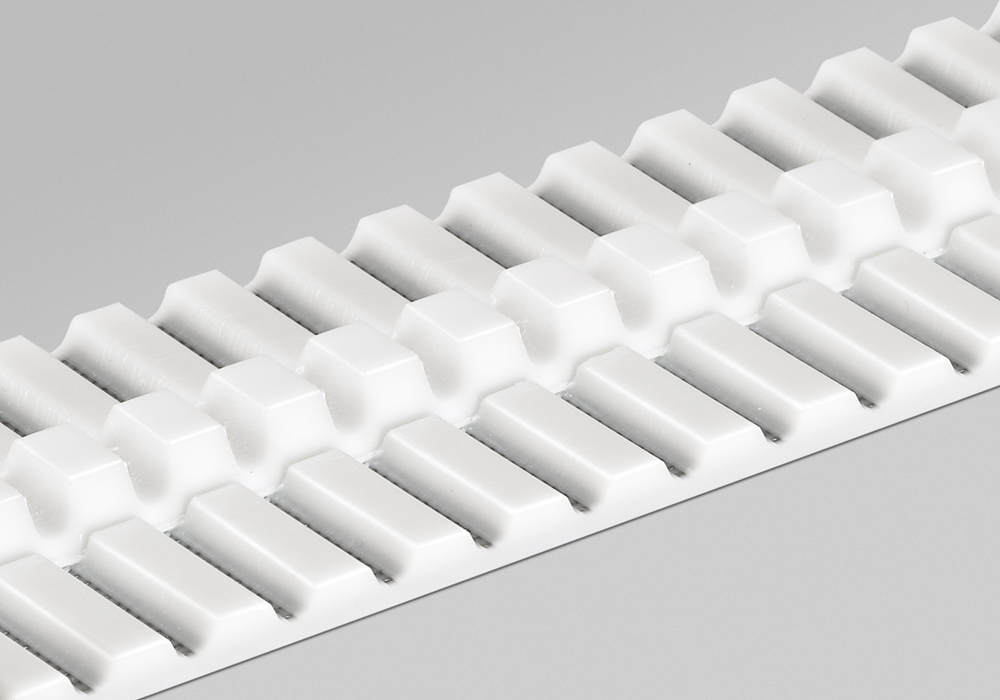

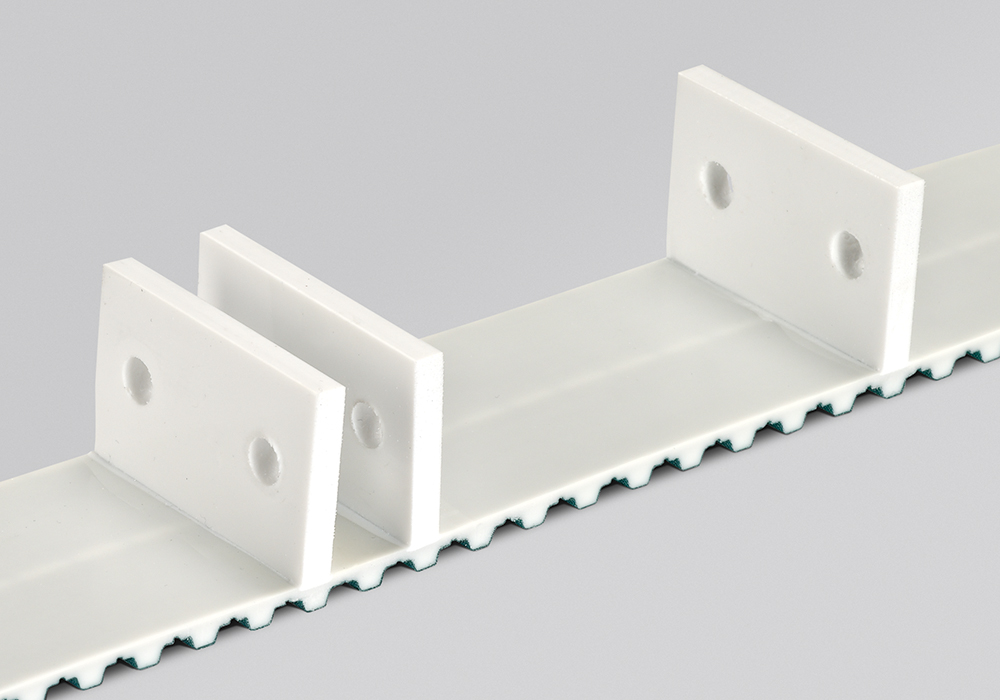

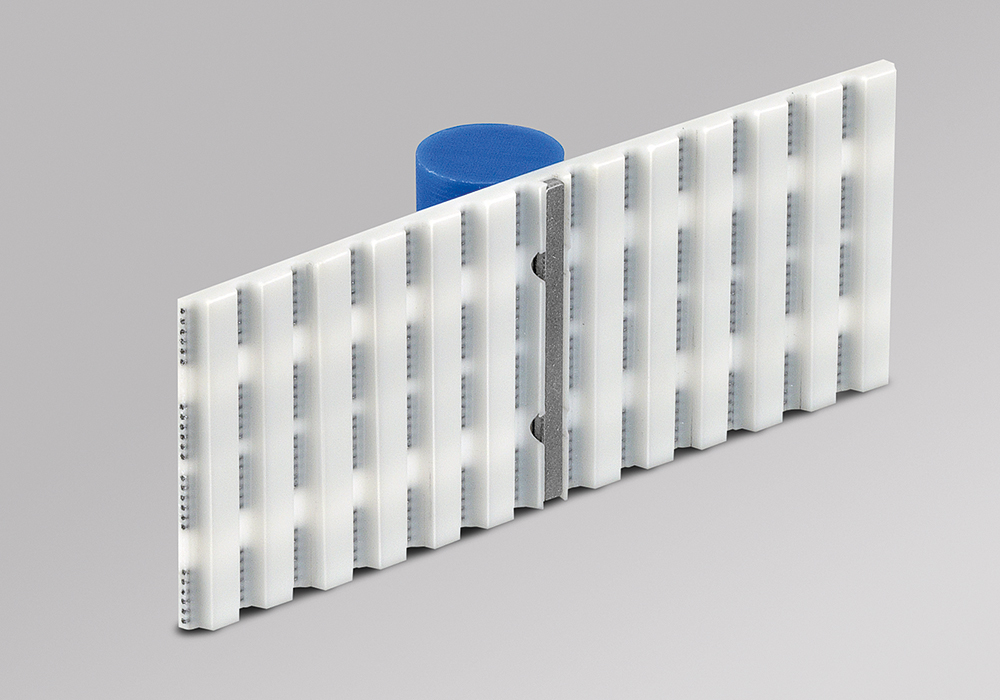

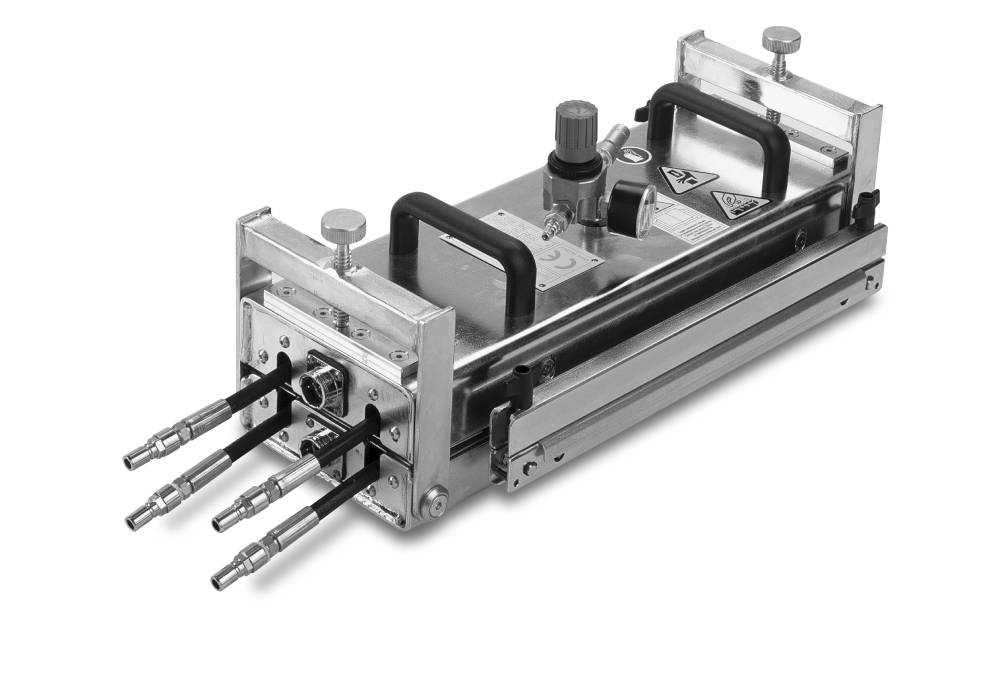

Making in-house belt fabrication possible

Effective and efficient fabrication of belts on site is made possible with the broad range of Habasit tools. The available equipment series cover the requirements of standard or specialized in-house fabrication, as well as on-site installations of belts and tapes.

Downloads