Swiss-quality, world-class-performance fabric belts

Fabric-based conveyor and processing belts are used in a vast number of industries and applications. Habasit’s wide-ranging offering extends from lightweight conveyor belts to specialized processing belts, and from power transmission belts to machine tapes.

Every Habasit solution is made with high precision and sets the performance benchmarks in the belting industry. We ensure the reliability and flexibility of our solutions through combining top-quality raw materials with state-of-the-art manufacturing and our extensive engineering experience.

Fabric Belts

Fabric conveyor belts surfaces

Select

Conveying surfaces feature a wide range of different structures to meet the demands of applications in the market. To learn about the various Habasit surface structures and their properties, just select the core features.

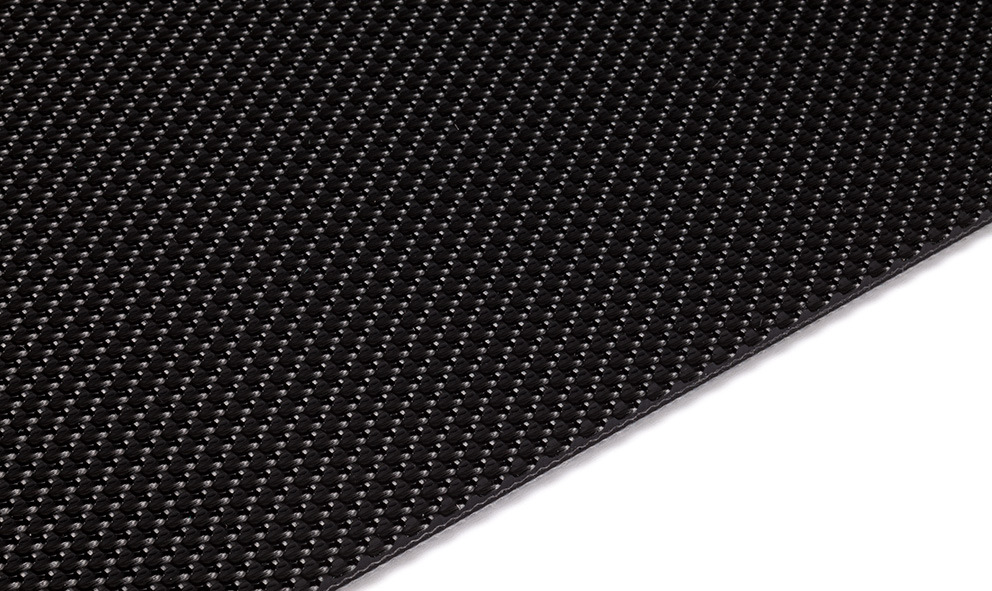

Basketweave structure

Buffed finish

Coarse textile structure

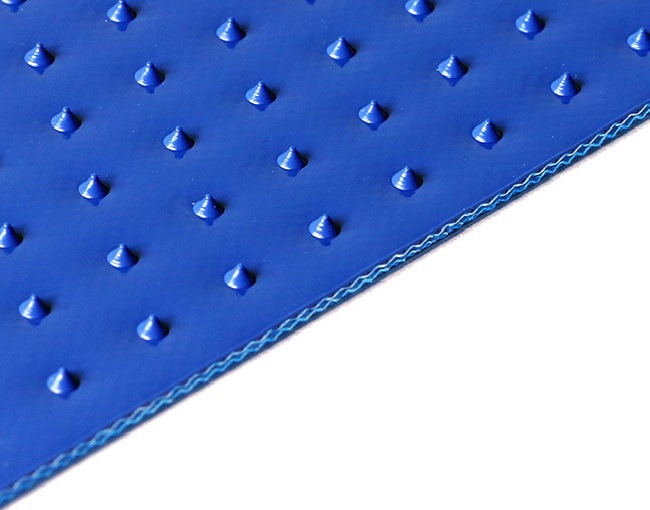

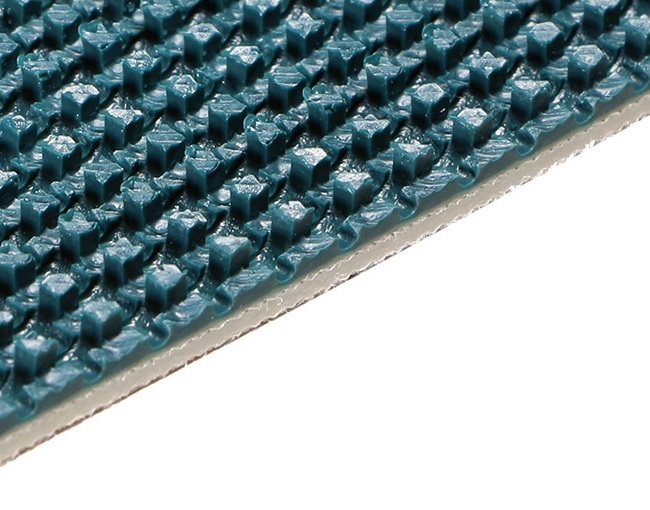

Cone top structure

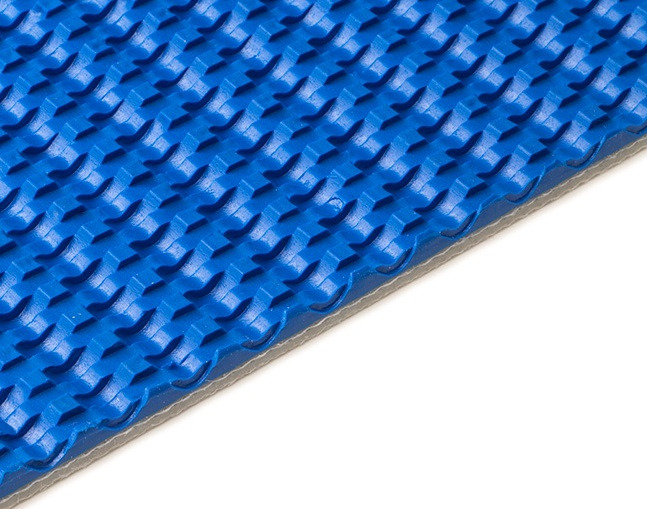

Crescent top structure

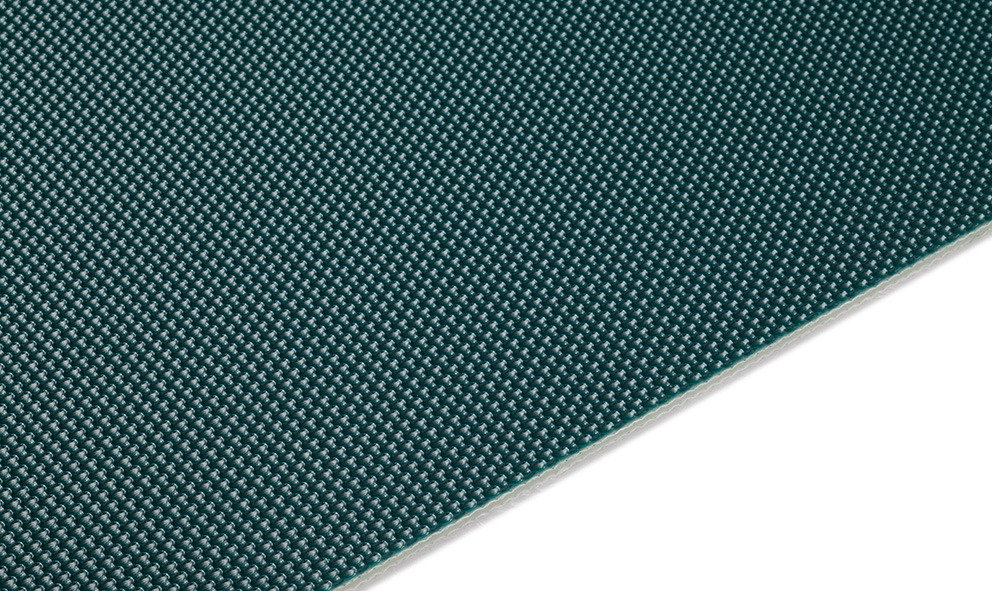

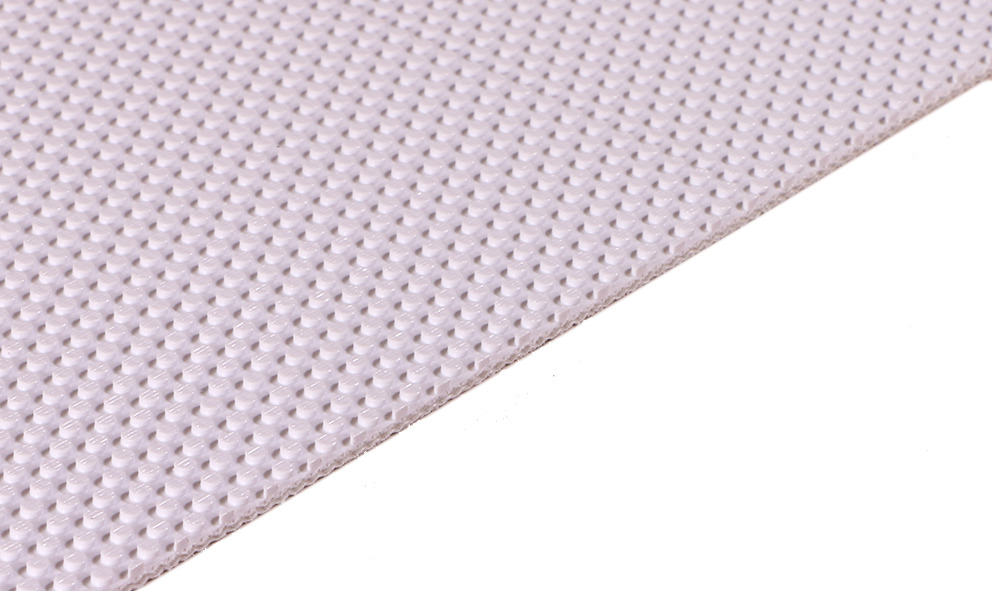

Cylindrical knob structure

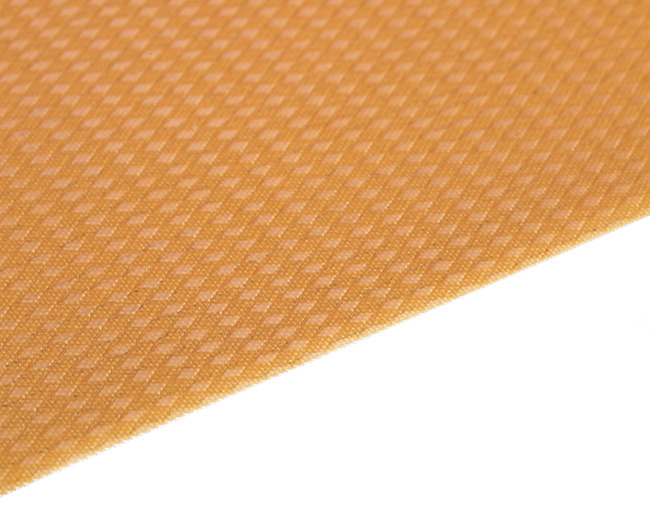

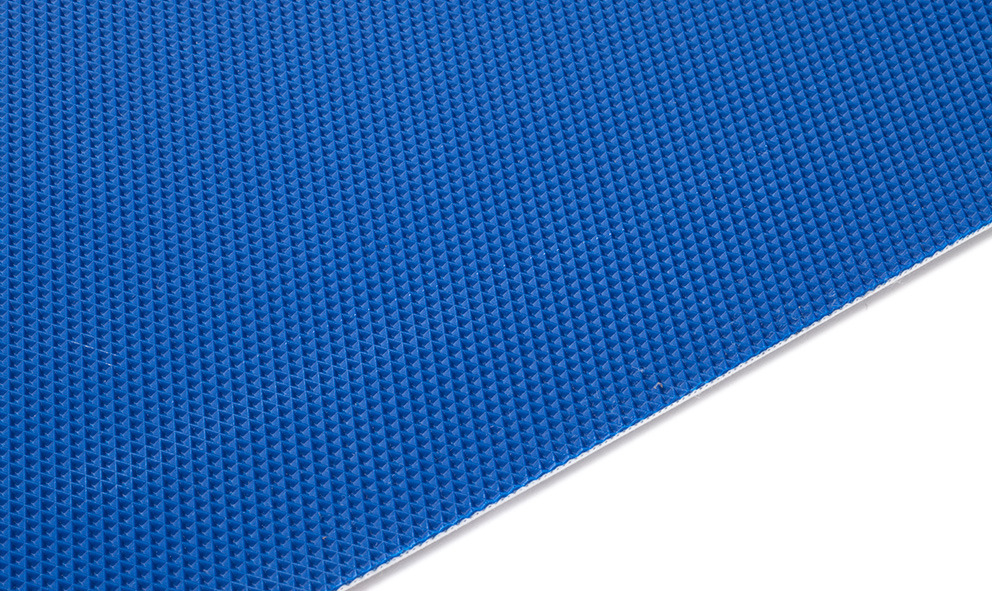

Diagonal rhomboid positive structure

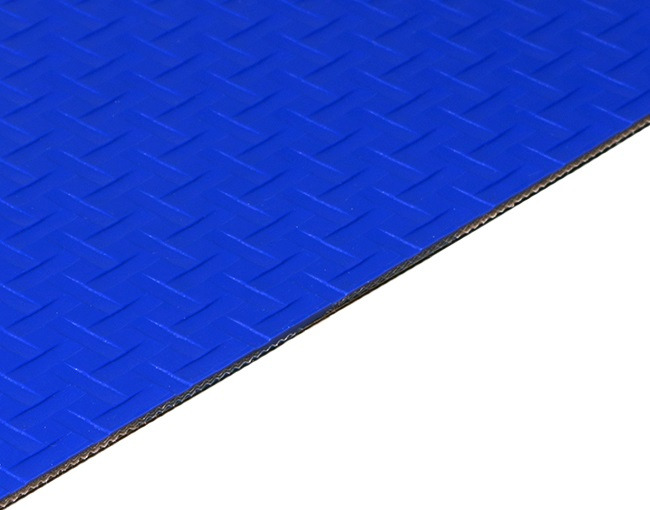

Diagonal wave structure

Elliptical smooth netting negative structure

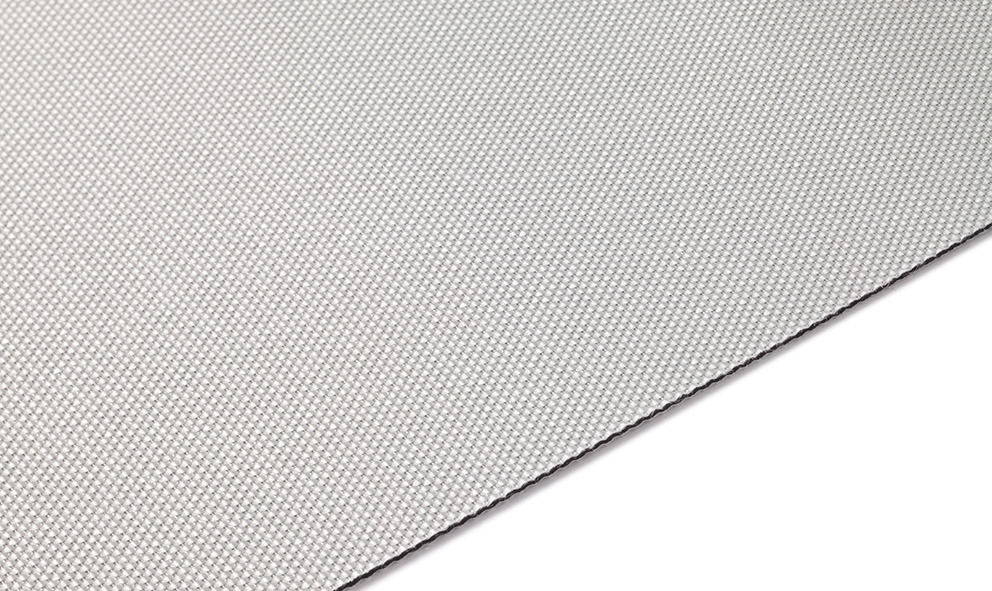

Fabric

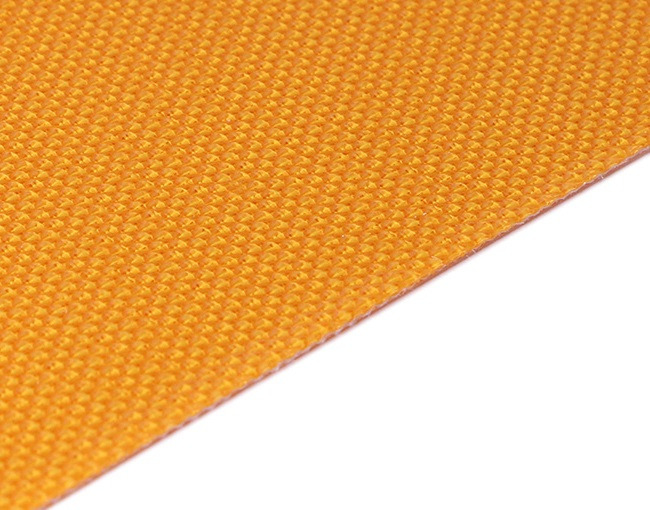

Fine textile structure / Fine weave emboss

Fish - herringbone structure

Glossy surface

Grip structure

Harlequin structure

Honeycomb structure

Impregnated fleece

Impregnated fabric

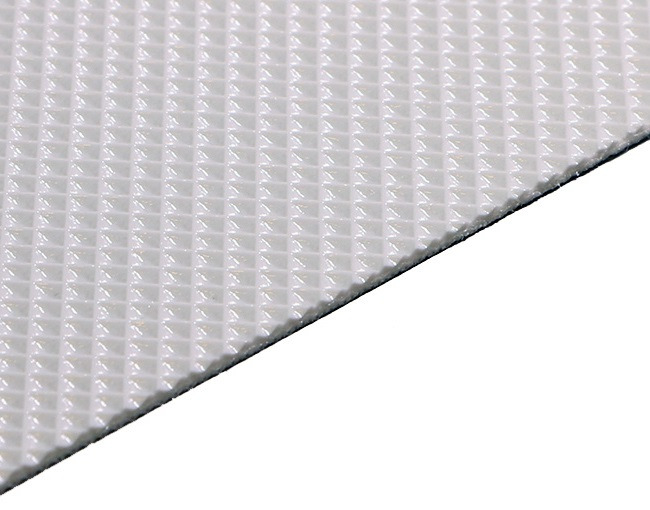

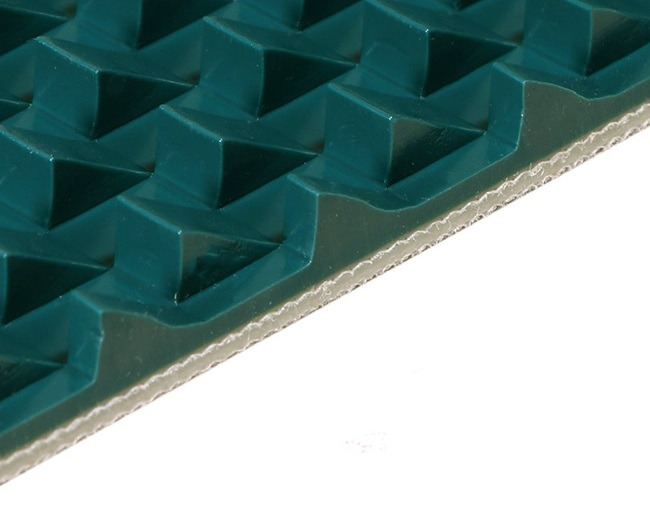

Inverted pyramid structure

Jink wave grip structure

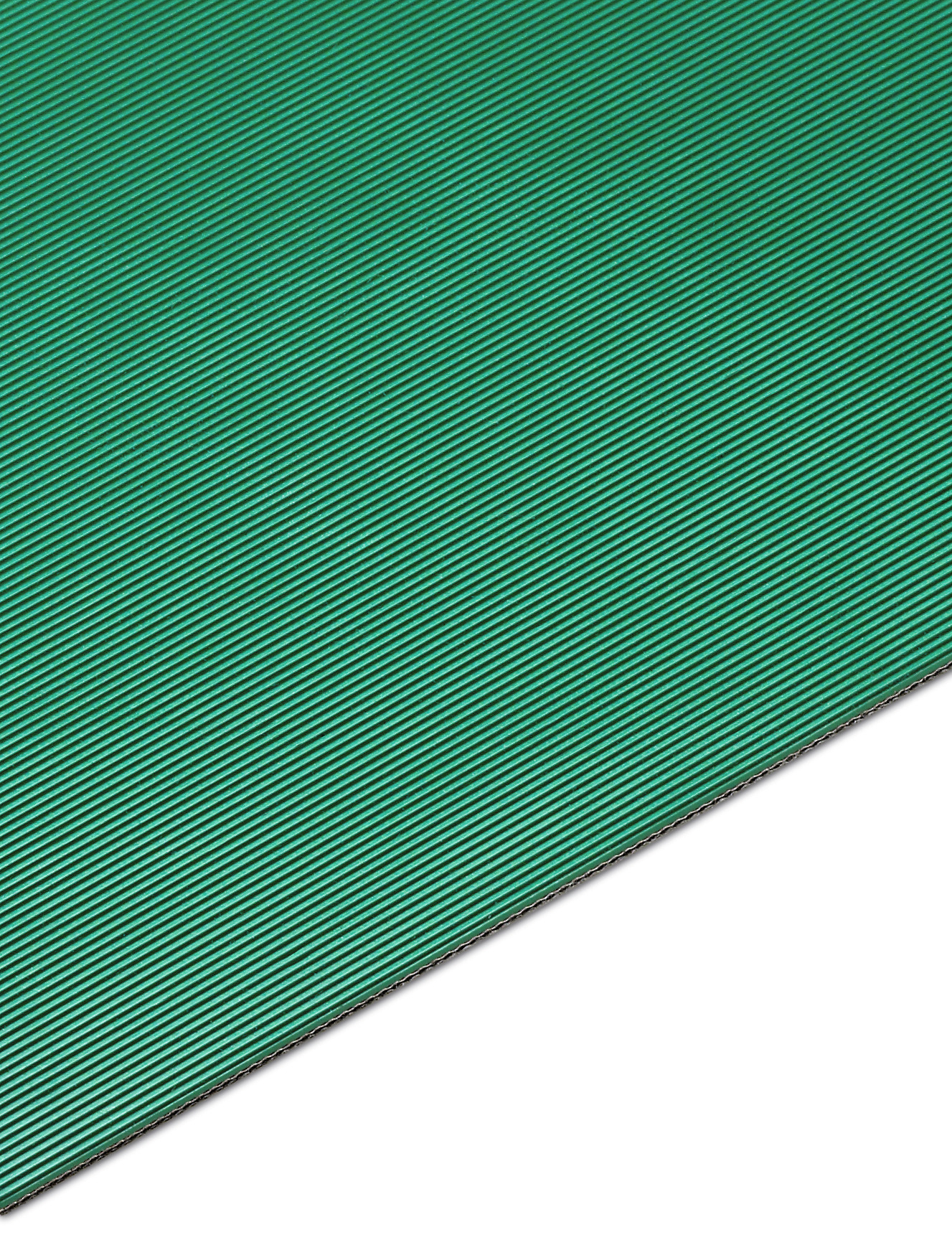

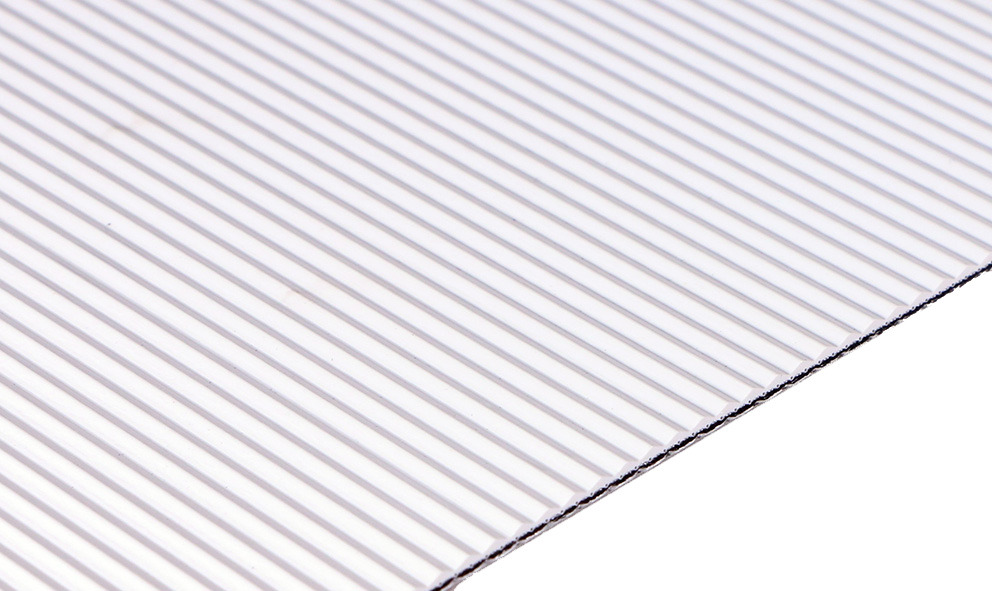

Longitudinal groove

Matt, dull finish

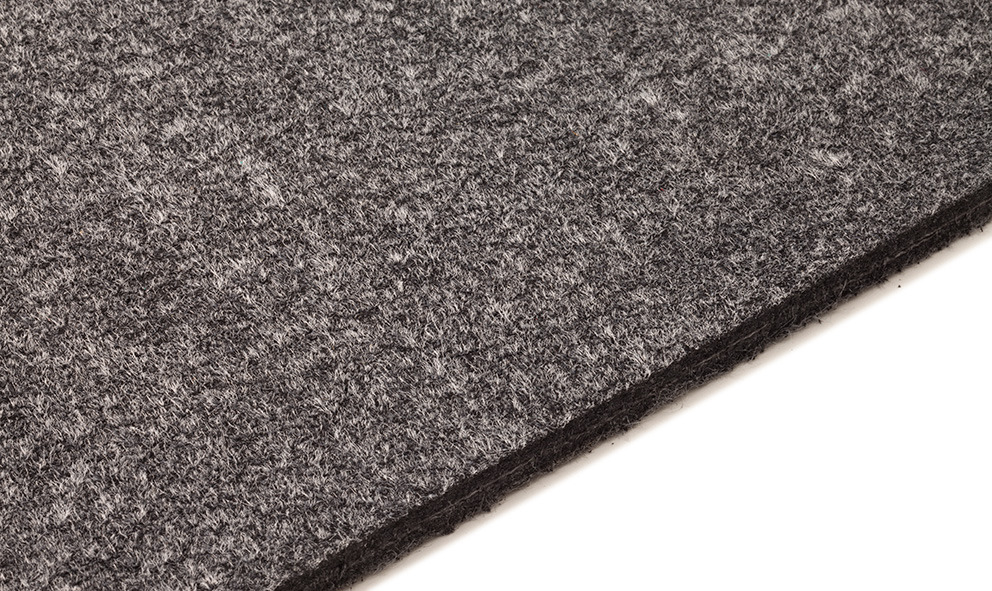

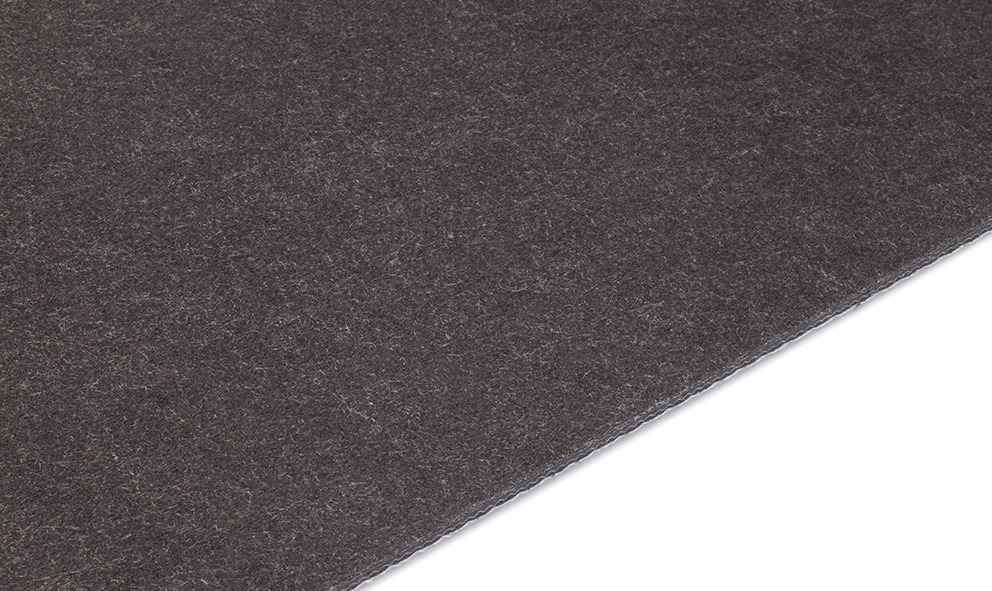

Non-woven (fleece) structure

Orange peel

Orb structure

Pimple structure

Quadrillé (quadrangular pattern)

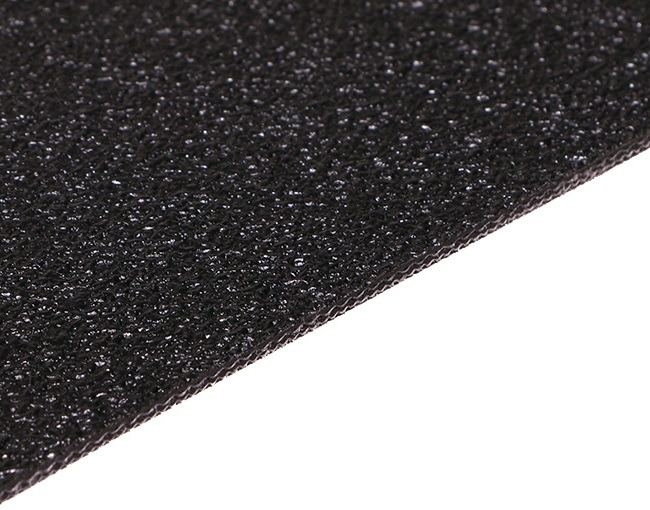

Sand finish

Sawtooth (large) structure

Sawtooth profile

Silk finish

Smooth

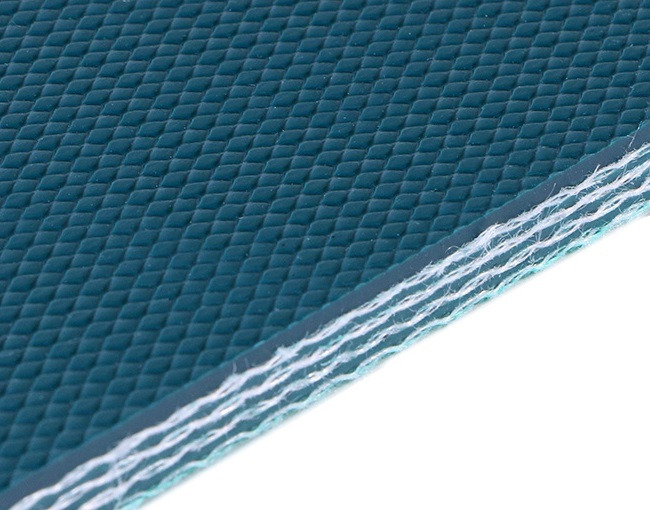

Snake skin structure

Square structure

Supermatt finish

Super grip surface

Tear drop structure

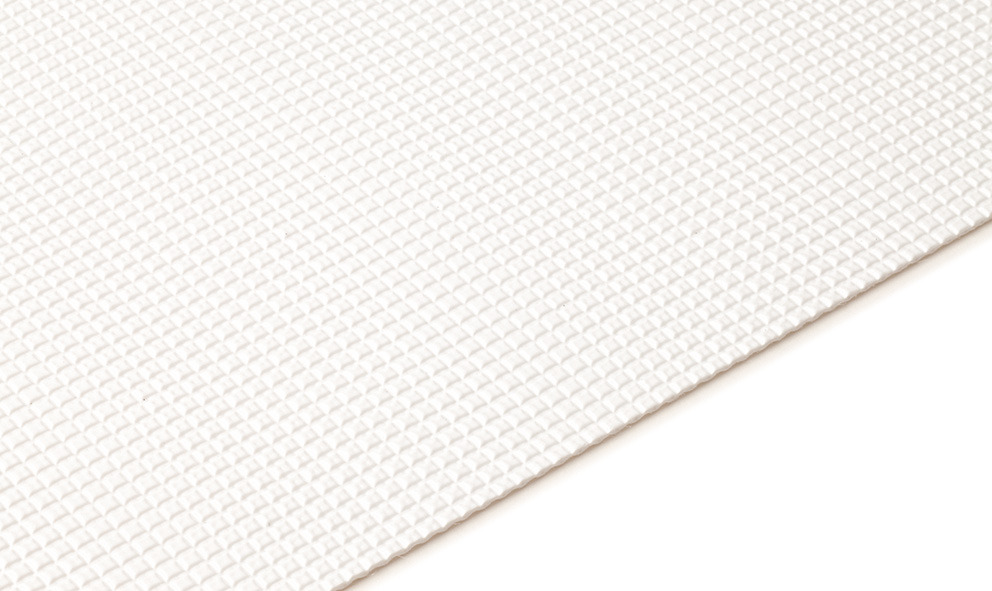

Waffle structure

Y Embossing

What's new?

Downloads