HabaSYNC timing belt covers –Habasit‘s cherry on the cake

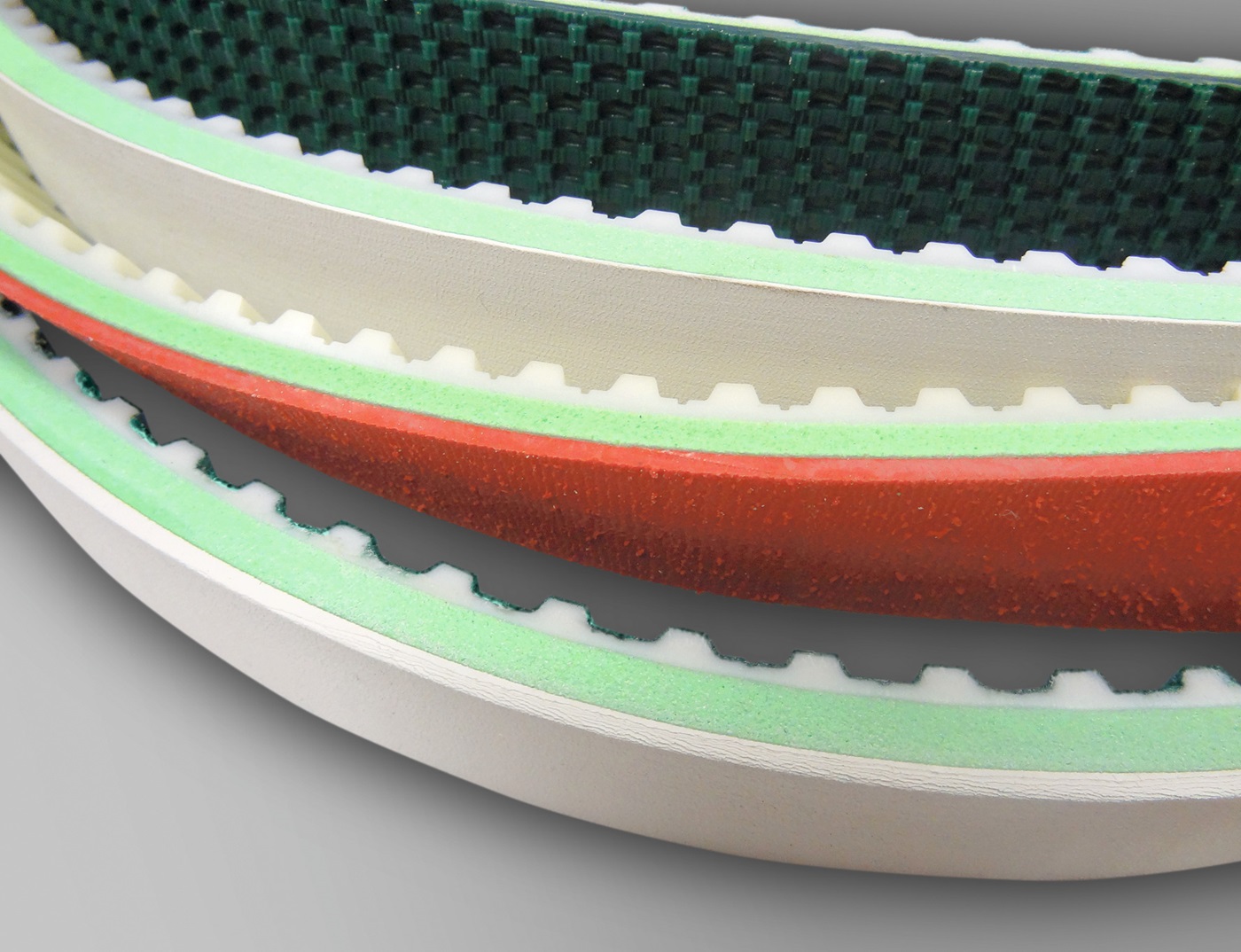

One crucial question when ordering at a café is: “With or without whipped cream?”. No matter if you add it on top of your hot chocolate or to your cake, for many of us, the white cream with a cherry on top makes a big difference. Just like with HabaSYNC. The Habasit timing belts have their very own cherry on top – the covers. With its range of more than 80 covers, Habasit offers tailor-made solutions for specific customer demands and has suitable covers for every industry.

One crucial question when ordering at a café is: “With or without whipped cream?”. No matter if you add it on top of your hot chocolate or to your cake, for many of us, the white cream with a cherry on top makes a big difference. Just like with HabaSYNC®. The Habasit timing belts have their very own cherry on top – the covers. With its range of more than 80 covers, Habasit offers tailor-made solutions for specific customer demands and has suitable covers for every industry.

There are almost no limits to the creativity of our engineers in finding the best fi t. Covers can even be

used in a different industry than originally developed for. Hence, sponge rubber covers can be found in tobacco plants or covers for the food industry are used in flat glass production lines. The product is equipped for a variety of customer demands and new requirements.

Every year we add new covers for timing belts to our portfolio. Amongst other options, the covers can be produced out of fabric belt material. These covers are exclusively produced by Habasit for HabaSYNC®.

Innovation and progress are important aspects in the further development of belt and cover material, but we also dedicate ourselves to the improvement of existing products. The goal is to enhance the design of successful timing belts for the individual requirements of customers or industries. This approach is reflected in a special product innovation for the food industry for which an entirely new manufacturing process has been implemented.

Closed flight

During the traditional manufacturing process of timing belts, a small groove originates between two teeth. This small groove is called flight. The product innovation for the food industry is the closed flight where the groove is filled with food grade Thermoplastic Polyetherurethane (TPU) which ensures smooth handling of wet foodstuff. The closed flight results in improved cleaning properties of the timing belt and prevents intrusion of bacteria and humidity. Our TPU is antimicrobial, provides good wear resistance on the tooth side and withstands hydrolysis, oils and solvents very well.

In the food industry precaution is particularly important. Thus we take preventative actions with product innovations like the closed flight or the selection of the belt color. In all stages of the production process, blue is the preferred color in the food industry. The reason behind that is simple: there are only a few blue food products. The blue belts offer a good contrast against the product which also supports the precision of applications with photo sensors.

Cherry on top of the cake

One must definitely not forget about the cherry on the top of the cake in the food industry. Therefore, Habasit offers 20 timing belt covers which fulfill various special requirements from meat processing to bakery applications. This also guarantees that the next cake baked will end up with a delicious cherry on top.

At the right place at the right time

“In HabaSYNC® timing belts one finds several valuable properties of conveyor techniques. They are positively driven like chains but with lower noise levels and low maintenance need. Just like fabric belts, timing belts are available in a huge number of variations and additionally they allow precise positioning at high speed. Timing belts position your product at the right place at the right time.”

Andreas Ebhart

Product Manager HabaSYNC®

There are almost no limits to the creativity of our engineers in finding the best fi t. Covers can even be

used in a different industry than originally developed for. Hence, sponge rubber covers can be found in tobacco plants or covers for the food industry are used in flat glass production lines. The product is equipped for a variety of customer demands and new requirements.

Every year we add new covers for timing belts to our portfolio. Amongst other options, the covers can be produced out of fabric belt material. These covers are exclusively produced by Habasit for HabaSYNC®.

Innovation and progress are important aspects in the further development of belt and cover material, but we also dedicate ourselves to the improvement of existing products. The goal is to enhance the design of successful timing belts for the individual requirements of customers or industries. This approach is reflected in a special product innovation for the food industry for which an entirely new manufacturing process has been implemented.

Closed flight

During the traditional manufacturing process of timing belts, a small groove originates between two teeth. This small groove is called flight. The product innovation for the food industry is the closed flight where the groove is filled with food grade Thermoplastic Polyetherurethane (TPU) which ensures smooth handling of wet foodstuff. The closed flight results in improved cleaning properties of the timing belt and prevents intrusion of bacteria and humidity. Our TPU is antimicrobial, provides good wear resistance on the tooth side and withstands hydrolysis, oils and solvents very well.

In the food industry precaution is particularly important. Thus we take preventative actions with product innovations like the closed flight or the selection of the belt color. In all stages of the production process, blue is the preferred color in the food industry. The reason behind that is simple: there are only a few blue food products. The blue belts offer a good contrast against the product which also supports the precision of applications with photo sensors.

Cherry on top of the cake

One must definitely not forget about the cherry on the top of the cake in the food industry. Therefore, Habasit offers 20 timing belt covers which fulfill various special requirements from meat processing to bakery applications. This also guarantees that the next cake baked will end up with a delicious cherry on top.

At the right place at the right time

“In HabaSYNC® timing belts one finds several valuable properties of conveyor techniques. They are positively driven like chains but with lower noise levels and low maintenance need. Just like fabric belts, timing belts are available in a huge number of variations and additionally they allow precise positioning at high speed. Timing belts position your product at the right place at the right time.”

Andreas Ebhart

Product Manager HabaSYNC®